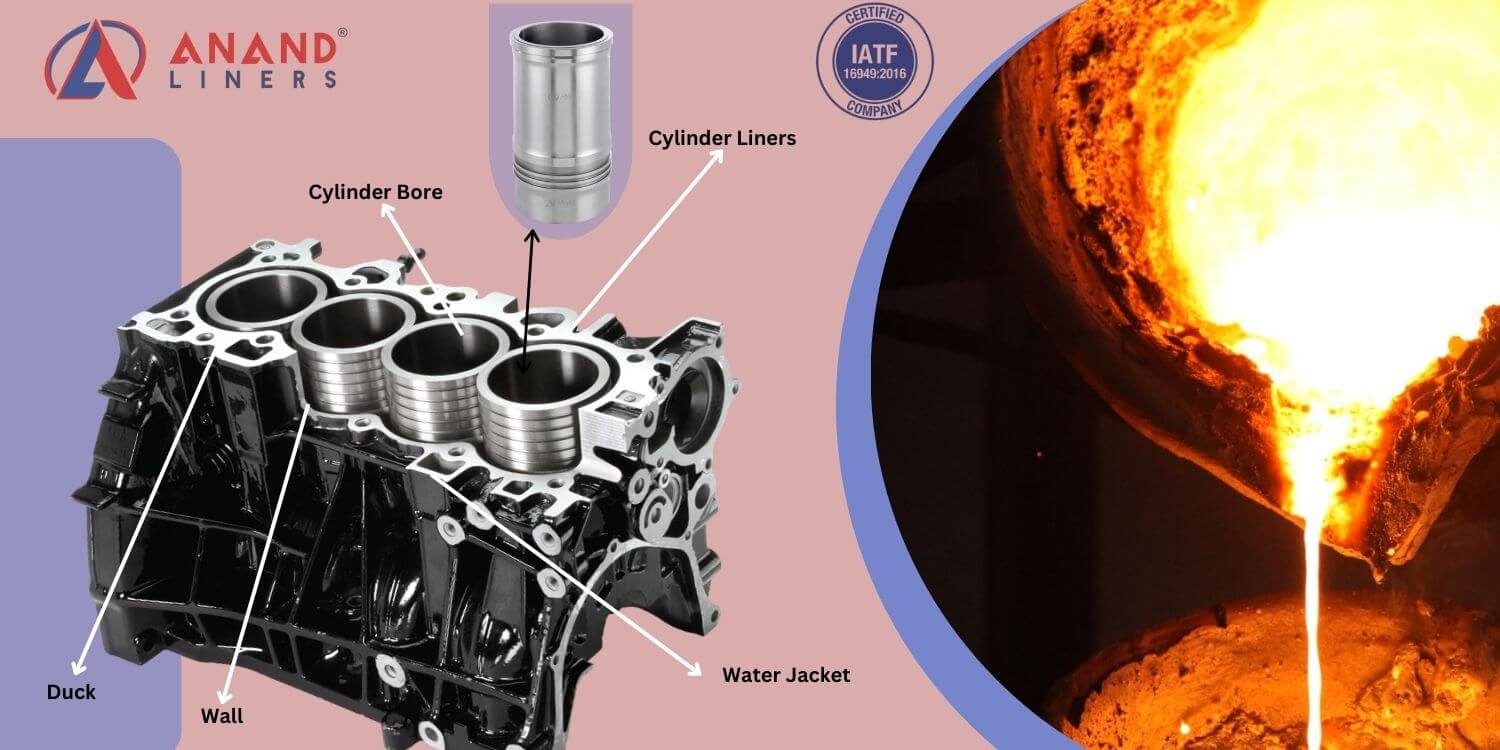

A Cylinder liners also known as a cylinder sleeve, plays a crucial role in enhancing the overall performance and durability of internal combustion engines. It is a cylindrical component inserted into the cylinder bore of an engine block, creating a durable surface for the piston to move against during the combustion process.

Cylinder liners are widely used in various internal combustion engines, from automotive to industrial and marine applications. To understand their significance, let’s consider a real-life example in the automotive industry.

Real-life example:

Imagine two identical car engines—one with cylinder liners and the other without. These engines undergo the same operating conditions, including high temperatures, pressure variations, and frictional forces.

In the engine without cylinder liners, the piston directly contacts the engine block’s cylinder bore. This leads to increased friction, wear, and heat generation. Over time, the lack of a protective barrier causes the cylinder bore to wear out, resulting in reduced engine efficiency, compression loss, and coolant leaks.

In contrast, the engine equipped with cylinder liners experiences numerous advantages. The liners create a durable and wear-resistant surface, reducing friction and wear between the piston rings and the cylinder wall. This improves engine efficiency, fuel economy, and overall performance.

Additionally, cylinder liners act as sacrificial surfaces that can be easily replaced when worn or damaged. This protects the engine block, extends the engine’s service life, and reduces maintenance costs.

Furthermore, cylinder liners enable precise control over engine tolerances. By selecting liners of different materials and thicknesses, engine designers can optimize the clearance between the piston and cylinder. This improves sealing, reduces blow-by, and enhances overall engine performance.

The presence of cylinder liners significantly enhances the performance and durability of internal combustion engines. They reduce friction, protect the engine block, optimize tolerances, and contribute to better overall engine efficiency.

Importance of cylinder liners in engines:

Beyond the example, let’s explore the importance of cylinder liners in engines, their benefits, and how they improve overall performance and longevity.

- Friction Reduction and Wear Resistance:

Cylinder liners provide a hard and durable surface for the piston, reducing friction and wear between the piston rings and the cylinder wall. This improves engine efficiency, energy losses, and fuel economy. Cylinder liners also offer excellent wear resistance, maintaining optimal performance over extended periods.

- Protection of the Engine Block:

Cylinder liners act as sacrificial surfaces, protecting the engine block from direct contact with the piston. They can be replaced independently, eliminating the need for costly engine block replacements. This extends the engine’s service life and reduces maintenance costs.

- Thermal Conductivity and Cooling:

Cylinder liners aid in the efficient transfer of heat from the combustion process to the engine coolant. This prevents overheating and maintains optimal operating temperatures. Proper thermal conductivity ensures the engine operates within a safe temperature range, reducing the risk of damage and enhancing longevity.

- Precision Engineering:

Cylinder liners enable fine-tuning of tolerances between the piston and cylinder. By using liners of different materials and thicknesses, engine manufacturers can optimize clearance. This precise control over tolerances improves sealing, reduces blow-by, and enhances overall engine performance.

- Material Selection:

Cylinder liners can be made from various materials, including cast iron, aluminum alloys, and composites. The material choice depends on factors such as engine type, operating conditions, and performance requirements. Each material offers specific advantages in terms of durability, heat dissipation, and compatibility with piston rings.

- Flexibility in Engine Design:

Cylinder liners provide flexibility in engine design, accommodating modifications and upgrades. Manufacturers can adjust liner thickness, diameter, and shape to meet changing specifications, fuel types, or power requirements. This adaptability facilitates the development of engines with improved power output, reduced emissions, and enhanced efficiency.

In conclusion, cylinder liners play a pivotal role in the performance, reliability, and longevity of internal combustion engines. By reducing friction, protecting the engine block, managing heat, and enabling precise control over tolerances, cylinder liners contribute to improved efficiency and reduced wear.

The replaceable nature also makes them a cost-effective solution for maintaining engine health. Advances in materials and design approaches continue to enhance the performance and durability of cylinder liners. Understanding the importance of cylinder liners empowers engine manufacturers and users to make informed decisions, leading to engines that deliver optimal performance and extended service life.

For more information about our products, visit our website: https://www.anandliners.com/

Call now – +91-98240-84840